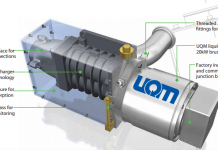

Earlier this week Westport Fuel Systems (WPRT: Nasdaq) announced a technology breakthrough with its high pressure direct injection system for truck engines using natural gas as a fuel. A new cryogenic pump has been development for high-horsepower applications and integrated into Westport’s fuel system, which has apparently been demonstrated at higher cylinder pressures. The company apparently plans to load the innovation, which it called Westport HPDI 2.0, into next generation diesel engines.

Investors interested in renewable energy or focused environmental improvements are probably wondering why this little company outside Vancouver, Canada could be important.

The uncomfortable truth is that the world’s addiction to fossil fuel will not be beaten easily. Great swaths of our global economy are highly dependent upon low-cost fuels for transport and power. The transition to more environmentally-friendly energy sources such as solar or wind cannot happen overnight. (Indeed, many are still concerned that with all renewable sources piled together, energy production will still fall short of the full force required to eliminate fossil fuels.) In the meantime, greater efficiency in the use of fossil fuels can make a contribution alleviating the harmful effects of greenhouse gases released by combusting oil, gas and coal.

It is efficiency that Westport delivers to its engine manufacturing customers. That should make it interesting to investors as well. To prove its mettle, the company got some help from AVL List GmbH, an independent testing firm for vehicle power trains. AVL recently presented a strong case for Westport’s HPDI system at the International Engine Congress in Germany, arguing that Westport’s system allows OEMs to meet or exceed future standards for reducing pollutant and greenhouse gases by using natural gas engines equipment with efficiency enhancements.

In the United States, the transportation sector is the largest source of greenhouse gas emissions. Light duty trucks are the source of over 60% of U.S. transportation emissions. Perhaps more problematic are medium- and heavy-duty trucks that make up only 5% of vehicles on the road but account for as much as 20% of U.S. transport greenhouse gas emissions.

The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) have set clean air standards in the United States for cars, small trucks and heavy-duty highway vehicles and the engines that power them. Phase I of these regulations cover vehicle model years through 2018, and Phase II picks up the baton through model year 2027. The two agencies estimate fuel savings will be over half a million barrels of oil per day in 2035, and by 2050 when the rule is fully phased in, the savings will increase to over 800,000 barrels per day. Improved fuel efficiency translates directly to reduced carbon emissions.

The European Union first introduced emission standards for engines that drive heavy-duty vehicle in 1988. This was well ahead of the U.S. but ultimately the two jurisdictions have adopted standards that are similar in stringency.

Of course, there are alternatives for engine and truck manufacturers to meet fuel efficiency and emissions regulations. The standards are meant to be technology neutral. Manufacturers may use any kind of technology or system to achieve compliance. Tires that provide for low rolling resistance or aerodynamic improvements are low-cost alternatives, but will not achieve the efficiencies that will fully meet standards down the road. Technologies related to transmissions and drivelines or idle reduction technologies are needed to meet standards that will come into force in the decade ahead.

U.S. and European standards are important hurdles for Westport’s engine manufacturer customers. They are incentivized to improve engine performance, creating a fertile environment for Westport’s sales engineers to cultivate strong customer relationships. The company recently inked a development and supply agreement with Tata Motors Ltd. for four- and six-cylinder natural gas spark-ignited commercial vehicle engines to meet emissions standards set by the Indian government that are to take effect in 2020. The new agreement extends a relationship that began in 2012.

Westport Fuel Systems claims more than twenty customers in the vehicle and engine market in over seventy countries. The company has also approached the market through partnerships with natural gas fuel providers like Royal Dutch Shell plc.

A joint venture with Cummins, Inc. (CMI: NYSE) is helping Westport Fuel Systems has put its own engines on the market – the Cummins Westport L9N and the ISX12N natural gas engine. Earlier this year, the joint venture announced that certification for the ISX12N had been received from both the U.S. EPA and the Air Resources Board of California for compliance with nitrogen oxide emissions standards. The Cummins Westport L9N had already been given certification.

Demand conditions appear quite favorable for Westport’s natural gas engine solutions. Now the question is whether Westport is a position to capture market share. In the twelve months ending September 2017, the company reported $290.4 million in total sales. Westport is still spending heavily on research and development. Furthermore, marketing and sales efforts have been ramped up to introduce the first products to customers. That means operating expenses still exceed gross profits, leaving Westport with operating losses. Net loss in the most recently reported twelve months was $84.8 million.

For investors who find the deep loss somewhat concerned, cash flow from operations provides a better perspective on financial condition. In the trailing twelve months ending September 2017, the company used $53.2 million in cash to keep operations going. Given the Westport had only $51 million in cash on its balance sheet at the end of September, investors would be right to question Westport’s ability to keep in the game. Since the close of the September 2017 quarter, Westport received a $20 million loan from Export Development Canada to support commercial launch of the Westport HPDI 2.0 program.

Westport has already lined up at least one customer for the Westport HPDI 2.0 program in Weichai Power Company, a state-owned enterprise in Shandong Province, China that designs and sells diesel engines. In December 2017, Weichai signed a memorandum of understanding so popular with China enterprise to lubricate the wheels of cooperation with suppliers.

Analysts are not expecting a flip to profitability in the near-term. The consensus estimate for 2018 is for a loss of $0.18 per share on $257.1 million in total sales. The sales target represents 8.5% year-over-year growth, which is encouraging but perhaps falls short of expectations some might conjure up given the pressure of standards compliance for Westport customers. An earnings loss is ordinarily negative. However, this case is also encouraging in as much as the loss is considerably lower than the most recent twelve months. Sales levels and profits may not be what investors might like to see, but Westport is at least moving in the right direction – ushering the dirtiest of fossil fuels to the door.